Flanges

Manufacturer, Exporters & Supplier of

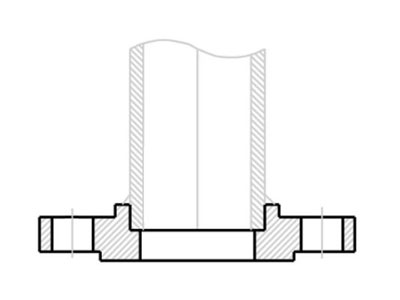

Threaded Flange

Threaded Flange

Threaded flange is connecting with pipe without welding. It is similar to slip on flange or a socket weld flange, fitted with a tapered thread (screw) inside the flange bore that is mounted on the pipe with corresponding external threads. In some cases a seal weld also applied in conjunction with threaded pipe flange.

Our Supply Range

Standard:ASTM A105, ASTM A182

Material:Carbon Steel, Stainless Steel, Alloy Steel

Size Range: 1/2'', 1'', 2'', 3'', 4'' to 24''

Pressure Class: Class 150 to 2500

Face: RF, RTJ

Though threaded pipe flange is available in different dimensions, threaded fittings mostly is used in small diameters pipeline. (Below 4 inch normally.)

On the other hand, it is not compatible with a pipe system in thin wall thickness, since there is no space for doing the threading.

Threaded Flange Types

The socket welding flange was firstly to use for stainless steel superheater, due to avoid cracking defects caused by thermal stresses in heating processes, and after years development it became a standard applications for all types of material.

Socket Welded Flange Face Types

There are two types of threaded flanges:

- One is to seal the two pipe ends with a certain sealing surface and a lens pad. This type of flange is mostly used for ammonia production. But it has been used less recently, and the lens pad has been replaced by a metal ring.

- The other type is the same as a normal flange, sealed with two flange sealing faces.

Facing Types

There are two facing types for threaded flange, raised face flange and ring joint flange.

Raised Face Threaded Flange

When the gasket surface area is above the bolted line of the flange, the raised face flange is easily identified. It is compatible with a wide range of gaskets, from flat to semi-metallic and metallic types, either ring or full.

The main scope of a raised face flange design is to concentrate the pressure of the two mating flanges on a small surface and increase the strength of the seal.

The height of the raised face surface depends on the flange pressure level, for example, for pressure classes 150 and 300, the height is 1.6 mm or 1/12 inch, and for the 400 to 2500 level, the raised face height is about 6.4 mm, or 1/4 inch.

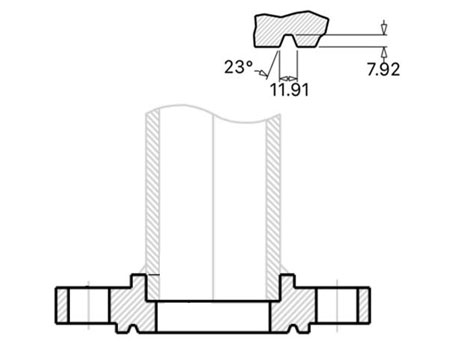

RTJ Threaded Flange

The ring joint flange has a circular groove to accommodate the ring joint gasket, which can be used when metal to metal seals are required. Especially in conditions for high pressure and high temperature.

Referred Standard and Grades

ASTM A105: Standard forged carbon steel pipe components for environmental and high temperature / high pressure systems.

ASTM A182: The standard for alloy and stainless threaded flanges. Common alloy grades: F5, F9, F11, F22, F91; Stainless steel grades: F304, 304/, F316, F316L.

Convenient Installation and Maintenance

The threaded flange is screwed to the threaded pipe by the thread, which is processed in the inner hole of the flange. So It does not need to be welded. Therefore, it became so convenient for installation and maintenance comparing with other flange types, such as slip on flange, socket weld flange etc.

Application in Special Circumstance

Threaded flanges are used where it is difficult to weld or cannot be welded, such as threaded flanges used to protect the galvanized layer of pipes. In addition, It should not be used on pipes with repeated temperature fluctuations or above 260 ℃ and below -45℃ as well.

In ASME B31.3 standard it defines:

Where steel pipe is threaded and used for steam service above 250 psi or for water service above 100 psi with water temperatures above 220° F, the pipe shall be seamless and have a thickness at least equal to schedule 80 of ASME B36.10.

Measurement

If threaded pipe flange can be measured accurately, following data shall be required:

- O: Outside Diameter of flange

- C: Thickness of flange

- R: Diameter of raised face

- X: Hub Diameter at base

- Y: Length through hub

- T: Minimum thread length

- Q: Minimum diameter of bolt circle