Gaskets

Manufacturer, Exporters & Supplier of

Gaskets

What is Gaskets?

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to create a static seal and maintain that seal under various operating conditions in a mechanical assembly.

Riddhi Siddhi Impex is a leading manufacturer, supplier and exporter of pipe fittings, forged fittings, tube fittings, dairy fittings, valves, Shims, Washers, Fasteners, Round Bars, Gaskets and flanges.

Standard Table Gaskets

We make standard tables such as ASA 150, British Standard Table ‘D’, ‘E’, ‘F’ & ‘H’ and PN6/10/16/25 & 40, ranging from ½” to 42” Series A and B, for use within all types of pipe works which can be made from a wide selection of materials to seal all types of liquids, gases and chemicals that the pipe may house.

Non-Asbestos Fibre (NAF)

Since asbestos was outlawed in 1999, we had to find replacement materials. Non-Asbestos Fibres (NAF) are currently available in a wide variety and can be employed in a wide range of applications.

Soft Cut

‘Soft cut’ is a common term within the cutting industry. To explain, this is the ability to cut any flexible material e.g. plastic, cork, rubber, non asbestos fibres. For a more comprehensive list, please refer to our materials section.

Novus Gaskets

As well as all of the above, we have a wide range of Novus available, including Novus 10, 26, 28, 30, 34 and 45.

High Temperature and Exhaust

Equally important is our ability to cut high temperature steel laminated gaskets, most commonly used within exhaust applications. As a matter of fact, we can cut materials from 300 to 1200 degrees Celsius, manufactured for both OEM and aftermarket.

Types of Gaskets we manufacture

1-Brass CW508L – CZ108 H/H

Brass CW508L, often referred to as CZ108 H/H, is a type of brass alloy commonly used for various industrial and manufacturing applications.

Brass CW508L, often referred to as CZ108 H/H, is a type of brass alloy commonly used for various industrial and manufacturing applications.

Key Details of Brass CW508L – CZ108 H/H:

Composition and Characteristics: Brass CW508L (CZ108) is a high-grade brass alloy consisting primarily of copper and zinc. This particular type of brass is known for its excellent cold working properties. It is classified as a “half-hard” brass, indicated by the “H/H” in its name, which means it has been work-hardened to a medium strength. This makes it more durable and resistant to wear compared to softer brasses.

Applications: This alloy is particularly favoured for its good corrosion resistance and excellent formability, making it ideal for fabrication processes such as bending and drawing. Common applications include:

Architectural and Decorative Components: Due to its bright gold-like appearance, it is often used in fixtures, fittings, and decorative elements.

General Engineering Parts: Components that require moderate strength and high corrosion resistance, such as fasteners, hinges, and brackets.

Electrical Components: Its excellent conductivity makes it suitable for connectors and terminals in electrical assemblies.

Brass CW508L – CZ108 H/H is versatile, reliable, and commonly used where both aesthetics and mechanical resilience are important. If you’re considering this material for your project or product, it offers a balanced mix of workability, durability, and visual appeal.

2-Cork Gaskets

Cork gaskets have a wide range of uses in both commercial and consumer applications

Cork gaskets are key where compressibility and flexibility are paramount. With a rubber composite, cork is water resistance, buoyant, fire resistant and highly impermeable.

Cork gaskets have a wide range of uses in both commercial and consumer applications

Cork gaskets are key where compressibility and flexibility are paramount. With a rubber composite, cork is water resistance, buoyant, fire resistant and highly impermeable.

We have a number of pure cork and cork/rubber composite materials are available. Including cork/silicone blends, cork/nitrile blends, cork/EPDM blends and many more different compounds. All of these options have their own specific properties and recommended usages.

Highly Resistant

As cork is both stable and lightweight, composite cork is ideal as a flexible and moisture resistant material. Additionally, it can withstand extremely high pressures without it being degraded, crushed or misshapen. Cork is also highly resistant to wear and tear.

In addition, it can withstand extreme temperatures as well as offering excellent sound resistant properties. To put it simply, composite cork is virtually indestructible.

3-Cork Pads

These pads are small pieces or sheets made from cork material. Cork is a natural substance harvested from the bark of cork oak trees.

These pads are commonly used to protect furniture surfaces from scratches, dents, and other damage. They are placed under the legs of furniture pieces like chairs, tables, and sofas to prevent them from scratching floors or leaving marks.

These pads are small pieces or sheets made from cork material. Cork is a natural substance harvested from the bark of cork oak trees.

These pads are commonly used to protect furniture surfaces from scratches, dents, and other damage. They are placed under the legs of furniture pieces like chairs, tables, and sofas to prevent them from scratching floors or leaving marks.

Cork pads can be used as noise dampeners. Placing them under the legs of furniture can reduce the noise generated when moving furniture across hard surfaces.

These pads provide a non-slip grip, helping to stabilize furniture on smooth floors. This prevents furniture from sliding or shifting easily, especially on slippery surfaces like hardwood or tile.

These pads are also popular for various crafts and DIY projects. They can be easily cut into different shapes and sizes, making them versatile for use in creative endeavors such as coasters, trivets, and bulletin boards.

Overall, cork pads offer practical solutions for protecting surfaces, reducing noise, improving stability, and adding a natural touch to DIY projects.

4-Cylinder Head Gaskets

Cylinder head gaskets are a particular type of gasket. Specifically, they are designed to sit between the cylinder head and engine block. Due to their design, they feature regularly in all types of internal combustion engines. However, most commonly in road vehicles such as cars and trucks.

Like any type of gasket, the purpose of it is to seal the gap between two surfaces. For example, the cylinder head and the engine block. This, therefore, ensures there is no leakage of either liquids or gases into or out of the join. Such as the leakage of exhaust fumes out of the exhaust system.

Over the years, head gaskets have been made from a number of different materials. Historically, graphite and asbestos was a common composite material. However, this came to an end due to environmental and health concerns over asbestos. As well, due to the fact that the materials were far more prone to head gasket blow-outs than more modern materials.

Nowadays, MLS (multiple layered steel) or copper gaskets are more popular. The reason being, copper gaskets allow the cylinder to bite into the gasket, improving the seal and the life of the gasket itself.

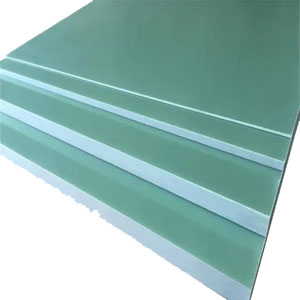

5-Epoxy G10

Epoxy G10 is a high-pressure fibreglass laminate made from layers of glass cloth soaked in epoxy resin, then compressed and heated to form a dense, solid material. It’s known for its excellent mechanical strength, low moisture absorption, and high electrical insulating properties.

Epoxy G10 is a high-pressure fibreglass laminate made from layers of glass cloth soaked in epoxy resin, then compressed and heated to form a dense, solid material. It’s known for its excellent mechanical strength, low moisture absorption, and high electrical insulating properties.

Key Characteristics of Epoxy G10:

- High Mechanical Strength: G10 is very strong and durable, making it suitable for demanding applications.

- Electrical Insulation: It is an excellent electrical insulator, crucial for many industrial and electronic applications

- Low Moisture Absorption: It resists moisture, ensuring stability and reliability in humid or wet conditions.

- Chemical Resistance: G10 is resistant to many chemicals, adding to its versatility in various environments.

- Chemical Resistance: G10 is resistant to many chemicals, adding to its versatility in various environments.

6-Exhaust Gaskets

A gasket is a mechanical seal designed to fill the space between two surfaces. Its purpose is to prevent leakage or seepage, both into and out of the joint between the two surfaces. For example, where two solid metal surfaces meet – like a join in a pipe. We use a gasket because the seal can never be perfect, therefore a gasket fills that gap and ensures that no liquid or gas can escape or enter the joint.

A gasket is a mechanical seal designed to fill the space between two surfaces. Its purpose is to prevent leakage or seepage, both into and out of the joint between the two surfaces. For example, where two solid metal surfaces meet – like a join in a pipe. We use a gasket because the seal can never be perfect, therefore a gasket fills that gap and ensures that no liquid or gas can escape or enter the joint.

Gaskets are a vital part of any exhaust and are generally made up of numerous sections. Vehicles especially, require an effective gasket otherwise, exhaust pipe fumes can escape into places they’re not wanted. For example, the passenger cabin or into the environment. Or, not having passed through the catalytic converter, meaning that the vehicle is considered unroadworthy.

7-Flexoid Gaskets

Flexoid gaskets are made from a plasticised material with gelatine infusion. Thus creates a cellulose-based compound that is highly resistant to many different liquid substances. Arguably, its best and most useful property is its resistance against petrol, oil, water and other fuels. Markedly, because it can seal against these liquids. In addition, it is an extremely cost-effective material and, therefore, is widely used in the automotive sector.

Flexoid gaskets are made from a plasticised material with gelatine infusion. Thus creates a cellulose-based compound that is highly resistant to many different liquid substances. Arguably, its best and most useful property is its resistance against petrol, oil, water and other fuels. Markedly, because it can seal against these liquids. In addition, it is an extremely cost-effective material and, therefore, is widely used in the automotive sector.

Although our chlorine-free flexoid gasket paper is ideal for the automotive industry. Due to its low heat and chemical resistance, it is not a common material within other industrial sectors. Furthermore, we do not recommend that it come into contact with alkalis, acids and steam. However, there are other alternatives for these types of applications, and they are normally non-asbestos materials.

8-Foam Gaskets

Our foam gaskets act as a ‘seal’ against certain elements and constituents. For example, if two components, such as pipes, push together to separate one part from the next, there is sometimes a risk of a gap. What this means is, it can be hard to guarantee that the seal is completely closed off. That is why gaskets are regularly used for additional support. At Riddhi Siddhi Impex, we manufacture various types of gaskets. Although, the materials in which they are made all depend on the application and what they will seal against.

The Benefits

These kinds of gaskets are different from solid rubber gaskets, as the material is a blown variant of standard rubber. As a result, this makes it a lighter and much more compressible gasket material. Another key point is that foam is very easy to manufacture and manipulate, which means the possibilities for bespoke gaskets are endless – in terms of sizes, shapes, and thicknesses. Additionally, they can be made either conductive or non-conductive, have great sound absorption and are fire retardant. Therefore making the gaskets suitable for a wide range of industrial environments. Foam is also ideal for hot and cold insulators, and is 100% recyclable – which makes it a great material to use for environmental purposes.9-Foam Pads

Foam pads are versatile components used in a wide range of applications, from industrial to everyday consumer products. These pads are made from foam material, engineered from different types of polymers such as polyurethane, neoprene, or silicone, to achieve specific properties like cushioning, insulation, or shock absorption.

Foam pads are versatile components used in a wide range of applications, from industrial to everyday consumer products. These pads are made from foam material, engineered from different types of polymers such as polyurethane, neoprene, or silicone, to achieve specific properties like cushioning, insulation, or shock absorption.

At Riddhi Siddhi Impex, our foam pads are available in various densities and thicknesses to suit a broad spectrum of applications. They are commonly used for sealing, padding, insulating, and protecting components in the automotive, electronics, and construction industries. The customisation options we offer allow you to choose the right type of foam and cut to specific dimensions to meet your project requirements effectively. Whether you need foam pads for vibration dampening in machinery, thermal insulation in appliances, or general cushioning and sealing, we provide high-quality solutions tailored to your needs.

What are the benefits of Foam Pads?

- Cushioning and Comfort

- Shock Absorption

- Vibration Dampening

- Thermal Insulation

- Acoustic Insulation

- Moisture Resistance

- Lightweight

- Cost-Effective

10-Insertion Rubber Gaskets

Gaskets act as a seal against elements or other components.

They are often used as a barrier between two different components (such as two metal pipes). When two parts are being used to seal a gap, it can be hard to guarantee a full seal.

A gasket can be used to completely close off any gaps. The material and thickness of the gasket will depend on the type of application it is being used in, and what it is sealing against.

Insertion rubber gaskets (cloth inserted) are cut from a material made from a blend of natural and styrene butadiene rubber with a single ply 22 gsm cotton reinforcement.

11-Interface 2331 Gaskets

Interface 2331 gaskets are high-performance sealing solutions widely utilised across various industrial sectors. These gaskets are renowned for their superior sealing properties, durability, and ability to endure extreme conditions.

Key Features:

High Temperature Resistance: Operate efficiently in high-temperature environments without losing performance.

Chemical Resistance: Withstand a wide range of chemicals, ensuring longevity in harsh environments.

Durability: Constructed from robust materials, reducing the need for frequent replacements.

Excellent Sealing Properties: Create a tight seal, preventing leaks and enhancing the performance of machinery and equipment.

12-Klinger Gaskets

The Klinger company pioneered the development of compressed fibre gaskets, otherwise known as Klinger gaskets. Since then, the name has been synonymous with the product. Much the same as the brand names of Hoover, Aspirin and Sellotape have become generic terms for their products. However, to many, they are simply known as compressed fibre gaskets.

The Klinger company pioneered the development of compressed fibre gaskets, otherwise known as Klinger gaskets. Since then, the name has been synonymous with the product. Much the same as the brand names of Hoover, Aspirin and Sellotape have become generic terms for their products. However, to many, they are simply known as compressed fibre gaskets.

Compressed fibre gaskets are manufactured using a carefully constructed blend of both rubber fibres and aramid glass. As a result, they have a malleable consistency, whilst remaining waterproof and resistant to a number of materials. In fact, it is this wide range of impressive properties which makes Klinger gaskets the material of choice in a number of industries and applications. In particular, the marine industry, and in major international oil pipelines.

13-Machined Spacers

achined spacers are cylindrical components fabricated from various materials to provide precise spacing and alignment between parts in mechanical assemblies. They are typically produced using machining processes such as turning, milling, and drilling, which ensure accurate dimensions and high-quality finishes.

Key Characteristics of Machined Spacers

- Material:Machined spacers can be made from metals (such as aluminium, steel, brass, or stainless steel), plastics (like nylon or PTFE), and sometimes composites, depending on the required properties like strength, corrosion resistance, or weight.

- Precision: These spacers are manufactured with tight tolerances to ensure exact spacing and alignment, crucial for high-precision applications.

- Dimensions: Available in various lengths, outer diameters, and inner diameters (if tubular), tailored to the specific requirements of the assembly.

- Surface Finish: The machining process provides a smooth surface finish, reducing friction and wear in assembled components.

14-Mica Gaskets

Mica gaskets represent the pinnacle of high-temperature sealing solutions, crafted from multiple layers of mica material infused with high-temperature silicone resin.

Offering thicknesses ranging from 0.5mm to 3.0mm, these gaskets are the epitome of versatility.

Why Opt for Mica Gaskets?

- Exceptional Thermal Insulation

- Unmatched Electrical Insulation

- Resilience to Chemicals

- Flexibility and Durability

- Minimal Thermal Expansion

- Safe and Non-Toxic

- Transparent to Radio Waves

- Built-in Fire Resistance

- Impeccable Sealing Properties

- UV Resistant

15-Neoprene Gaskets

Neoprene is a specific form of rubber, ideal for use in a number of applications as a gasket. In terms of its properties, it has a good level of strength and is resistant to weathering, ageing and abrasion. As well as thicknesses typically ranging from 1/64″ to 3/8″. As a result, there should always be neoprene gaskets to suit your needs. But if there isn’t, no problem because we offer bespoke manufacturing of any product.

Ideal For Underwater Use

Neoprene is often found in the aquatic leisure industry, most commonly in diving wetsuits. The reason being that its stretchiness and insulation properties make it the ideal material for underwater use. Not to mention the fact that it’s waterproof. In addition, it performs very well under water pressure. Therefore, it is a very highly performing material in the depths of the oceans.